Bamboo wood

Bamboo is a rapidly growing, ecologically neutral product, which regenerates itself, growing to full maturity within 5 years. From a biological point of view, bamboo is classified as a grass and rates as the plant with the fastest growth rate.

Bamboo for commercial usage is largely produced in commercial plantations in the mountain regions of China. The harvesting and processing of bamboo for bamboo-wood and bamboo flooring applications is not associated with any notable waste or polluting processes. All parts of the bamboo plant are utilized and over the last ten years the demand for bamboo products has grown enormously.

Bamboo is becoming ever more trendy and can be used for the manufacture

of a number of products including furniture, flooring, blinds, clothing,

paper, domestic articles and more.

genus Phyllostachys

a very productive plant group

The species Phyllostachys edulis is widely known for the commercial production of bamboo flooring, panels and other products. Due to its extremely rapid growth, tallness and large diameter, this plant is ideal for commercial production purposes.

Versatile plant

with many kinds and forms

Bamboo is extremely diverse with many kinds, forms and growth habitats. There are 91 genera and up to 1,500 species. In size, bamboo varies from small annuals to giant timber bamboo plants. Bamboo is the fastest growing woody plant in the world.

Widely distributed

with habitats from sea level up to high mountain locations

The many bamboo species are distributed through Asia, South and Central America, Africa and northern Australia. The highest concentration of species diversity is found in tropical and subtropical areas, especially the Asian region.

Bamboo as raw material

Competitive and cost-effective

The competitiveness of the bamboo products industry relies on it being a low cost, low-risk raw material, which at the same time has a high yield and rapid growth, allowing it to be harvested within three or five years.

Bamboo forests

An important commercial resource

The forests in the region around Anji in Zhejiang province in eastern China provide a substantial part of the bamboo, which is used for the production of flooring and related products. Situated approximately 85 km away from the coastal port of Hangzhou and about 220 km from Shanghai, Anji has a vibrant industry of bamboo products of all kinds.The advantages of compressed bamboo flooring at a glance:

- Blends in well with its surroundings and gives a solid hardwood impression.

- Robust and harder than most hardwood floors.

- Natural resistance to scratches, stains and heat.

- Sustainability: bamboo renews itself in five, a normal hardwood in 60 years.

- Good value for money compared with traditional hardwood floors.

Renewable high density flooring - the ecological choice

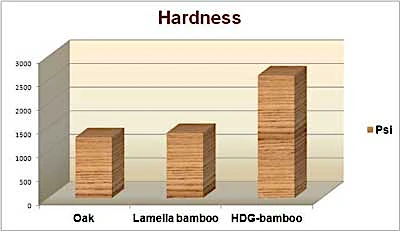

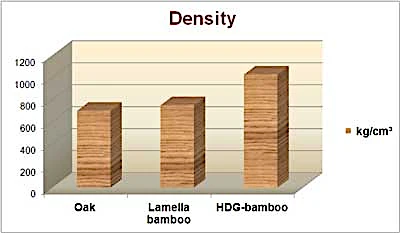

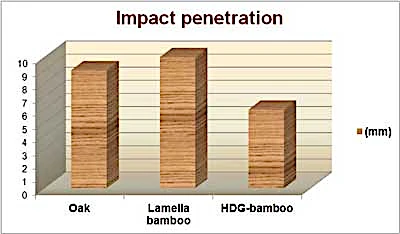

Compressed strand woven bamboo displays beneficial characteristics such as extreme hardness, compression resistance, impact resistance and form stability. Our flooring products have hardness exceeding that of the most wood types commonly used for flooring thereby offering an alternative to threatened tropical woods such as teak, doussie, merbau, wenge, Ipe, jatoba, mahogany and others.

Compressed "Bamboo wood"

Bamboo flooring can be supplied as solid single ply planks or in 2-ply, 3-ply or multiplex engineered formats. Our product palette includes strand woven bamboo, horizontal bamboo and vertical bamboo flooring.

Parquet boards and planks are available in click format for floating floors and in tongue and groove formats for glue down applications. Bamboo floors can be supplied in a range of colours from natural (light), Carbonized light and dark, and even in "Tiger" the high contrast striped format.

Surface treatment comprises matt or satin gloss lacquer (Klumpp or Bona) and oiling. High density strand woven bamboo flooring is suitable for residential use as well as for commercial high floors with high traffic loads.

In summary, bamboo offers a fashionable, contemporary and reliable material for flooring in the home and work place. It comes in several colours, is durable, hard wearing and a cost effective option for both new builds and renovations.

ChemAxis Lifestyle

Should you be interested in finding out more about these products, please contact us for further information, offers, orders and deliveries of bamboo flooring products.